Balancing

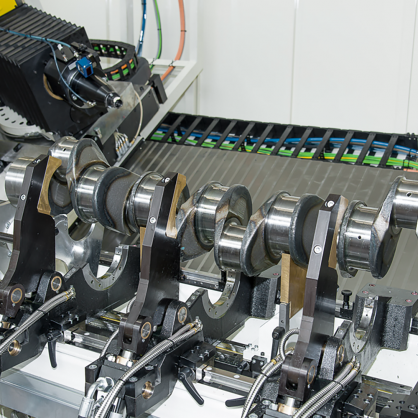

At CEMB Hofmann UK we specialise in balancing.

In other words, our expertise lies in correcting all areas of “unbalance”, which according to DIN/ISO 1925 is “that condition which exists in a rotor when vibratory force or motion is imparted to its bearings as a result of centrifugal forces.”

When the mass centre axis of a rotor is different to its running centre axis, unbalance is the result. Unbalance causes centrifugal force, noise and vibration during rotation – all of which increase in strength at higher speed, becoming more noticeable.

This uneven distribution of mass and consequent vibration is extremely damaging to the bearings of a rotor and its supporting structure.

The process of balancing is focused on improving the mass distribution of a rotor so that a smaller centrifugal force is at play on its bearings.

We specialise in the provision of both static and dynamic balancing machines, as well as a highly acclaimed UK contract balancing service.

Balancing of Rotors

Products with unbalanced parts will inevitably suffer from a shorter service life as a consequence of the high levels of stress imposed on bearings and suspensions by excessive vibration.

The vibration caused by unbalance can also affect the operating safety of a product as components become loose or even fracture.

Cemb Hofmann UK operates a world-class contract balancing service which addresses the unbalance in rotating parts to minimise vibration, structural stress, power loss and noise. As a result, the bearing life, quality and safety of all balanced parts is increased.

Types of Balancing

As defined by the ISO standard 1925, unbalance falls into four distinct categories:

- Static Unbalance

- Couple Unbalance

- Quasi Static Unbalance

- Dynamic Unbalance

During the process of balancing, it is crucial that the type of unbalance at play is identified so that correct methods can be applied to address the problem.